Luxury Industry

The surface chemistry is a technology that consists of modifying the properties of material surfaces at the nanoscale. This technology is widely used in the luxury industry to improve the quality, durability and appearance of high-end products. The jewelry, leather goods, cosmetics, watchmaking, and fragrance industries are some examples of sectors where surface chemistry plays an important role. Indeed, it allows for smoother, more wear and stain-resistant, and more brilliant surfaces. Surface chemistry is therefore essential for creating high-end products that meet consumers’ high standards for quality and aesthetics.

Read more below why SiKEMIA is the ideal partner for you.

Jewelry Industry

Surface chemistry is a cutting-edge technology used in the jewelry industry to improve the quality and durability of jewelry. Surface treatments are used to enhance the wear and corrosion resistance of precious metals such as gold, silver, and platinum. Thin film deposition techniques such as sputtering and vacuum evaporation can deposit very thin layers of materials such as titanium and diamond onto precious metals to improve their wear and scratch resistance. Precision polishing and engraving techniques can also create smoother and more precise surfaces for more aesthetically pleasing and durable jewelry. Surface chemistry is therefore essential for the production of high-quality, premium jewelry.

Leather Goods Industry

Surface chemistry is a crucial element in the leather industry. Surface treatments can be used to modify the properties of leather, thereby enhancing its quality and durability. They can also provide luxurious finishes such as pearlescent effects, soft or glossy textures, or metallic colors. High-end leather goods such as handbags and wallets can also benefit from surface treatments, strengthening their resistance to wear and tear and protecting against scratches and stains.

In summary, surface chemistry is an essential tool for the luxury leather industry, allowing it to create high-end products with improved properties and exceptional aesthetics.

Cosmetic Industry

In the cosmetics industry, pigments are used to add color and texture to cosmetic products. However, these pigments can sometimes be unstable or not easily blendable in formulations. To address this, the use of surface treatments by chemical means is common.

Surface treatments improve the dispersion and stability of pigments in cosmetic formulations. Pigments can be treated with surfactants to improve their wetting and dispersion in formulations, which allows for a more even distribution of color. Surface treatments can also help improve water and sweat resistance of pigments in cosmetic products.

The use of chemical surface treatments is also common to improve the performance of pigments in cosmetic products, such as adding anti-static agents to reduce static electricity and adding film-forming agents to help protect the color and texture of cosmetic products.

In summary, the use of chemical surface treatments is essential for improving the performance and stability of pigments in cosmetic formulations, allowing for the creation of high-quality, long-lasting makeup products.

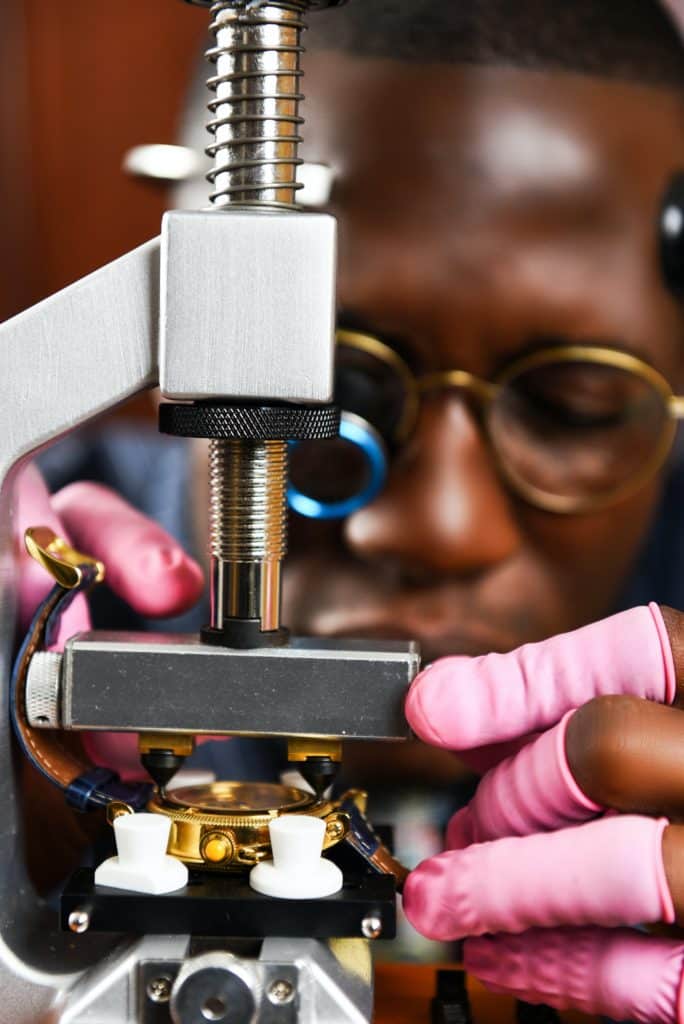

Watchmaking Industry

In many industrial fields lubricant is the key. That is why SiKEMIA has developped strong coupling agent helping our partners to control this process

Epilames are partially fluorinated molecules contained in a supporting fluid. They are applied either by immersion, spraying or pad printing. Epilamization consists in coating a substrate with a partially fluorinated polymer layer that reduces its surface tension to form a kind of “chemical barrier” that prevents oils from spreading out. As a result, sensitive areas of the component remain free of lubricants – contamination or damage is avoided.